Spring Strength Calculator

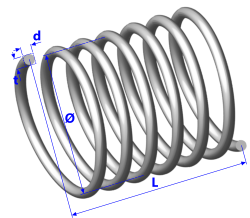

Fig 1. A Helical Spring

A spring will compress until it locks or extend until it remains unravelled (i.e. exceeds yield).

Material

The calculations in the spring strength calculator remain valid for any cross-section or material for which you enter the properties. However, the other properties that do not feature here but which should be considered are:

1) Its brittleness and/or toughness – never design a spring to use more than 45% of its Minimum Specified Yield Stress (material strength)

2) Wire cross-sectional properties – should be such that it locks solidly when it closes fully. I.e. the helix should not deform laterally with any significance unless special circumstances dictate otherwise and any such deformation is controlled.

Spring Strength Calculator - Technical Help

Units

You may use any units you like, but you must be consistent.

Input Data

The force (F) may be applied -ve or +ve for either tension or compression. The associated deflection (δ) will be in the same direction as the applied force.

If you enter a specified deflection (δ) in the spring strength calculator, the associated input force (F) will automatically reset to zero, and vice-versa

The mean diameter (Ø) of the helical spring should be between the structural centres of the wire's cross-section.

't' is the longitudinal thickness (at 90° to axis y-y; see Fig 1) or diameter of the wire used to make the spring.

The maximum stress will be achieved at the outside diameter of round wire or at the furthest (innermost) corner(s) of square/rectangular wire. This should be considered when selecting a value for r.

Output Data

The stress (τ) calculated in the spring strength calculator is the torsional shear stress in the material at deflection 'δ' and defines the spring's strength. A correction factor based upon the Spring Index (SI) has been applied to this stress to account for the intensified shear stress in the wire material on the inside of the coil.

In order to find the stress at maximum deflection, you should copy the output value for δmax and paste it into the input data value for δ.

Further Reading

You will find further reading on this subject in reference publications(2)